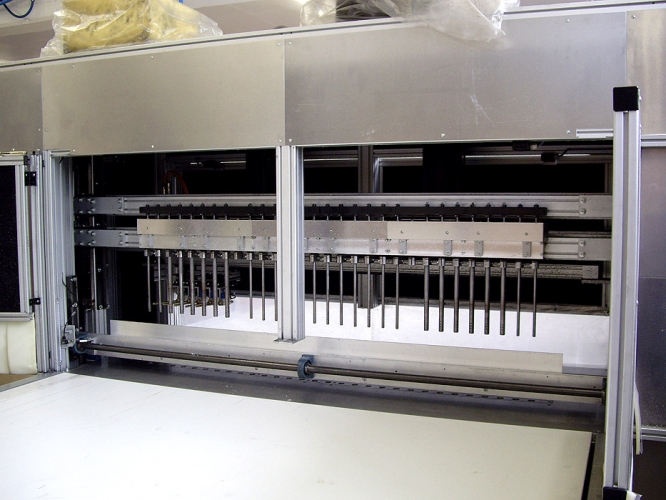

M 242 Mattress drilling machine

Holes are drilled across the length and breadth of foam mattresses with dimensions of max. 2.200 x 2.200 x 220 mm. The holes serve to provide better breathability.

The mattress is placed with its front end beneath the drill unit. Now the automatic drilling cycle begins. The clamping plate comes down on to the mattress and compresses it in the area where the drill is working so that the foam does not tear during the drilling process. The drill unit comes down and the hollow drills bore through the foam. As soon as the drill unit reaches the other side, the ejector unit comes down and and each hollow drill is shot through with a peg. That makes the remains of the foam fall out. The ejector unit, the drilling unit and the clamping plate travel back up to their original positions. The slider pushes the mattress forward (distance is set on the control panel beforehand), so that the next row of drillings can be dealt with. An extraction unit is not necessary.