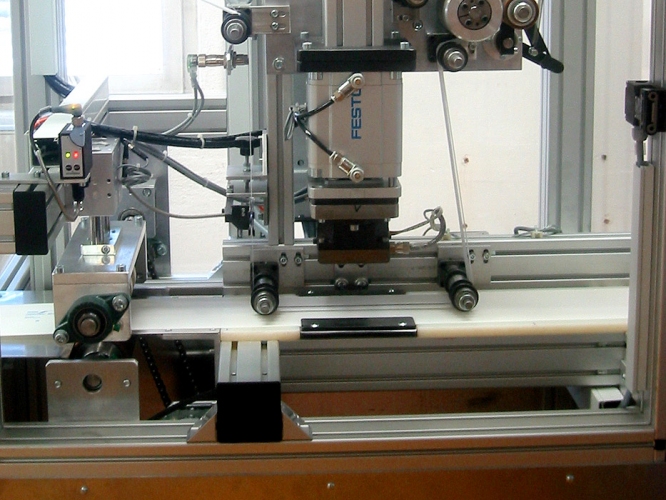

M 234 Multi-needle sewing machine for floor cleaning cloths

A fully automatic multi-needle sewing machine with 15 sewing stations is used to carry out different stages of the production of various mop types (single, double and triple). Simple and quick change-over operations at the different sewing stations enable operators to switch over from one type to another.

The basic materials are drawn from a triple dispenser and taken to the machine. During the process they are monitored by photocells. In the sewing machine the mop head is edged and seamed several times. After the sewing stage, the head is cut to length by a cross-cutter and stacked in a 2 compartment stacking box. The length of the head is determined by a positioning photoelectric barrier and a shaft encoder. A printing station is pre-connected to the machine so that the upper side of the mops can be provided with whatever printing is required.